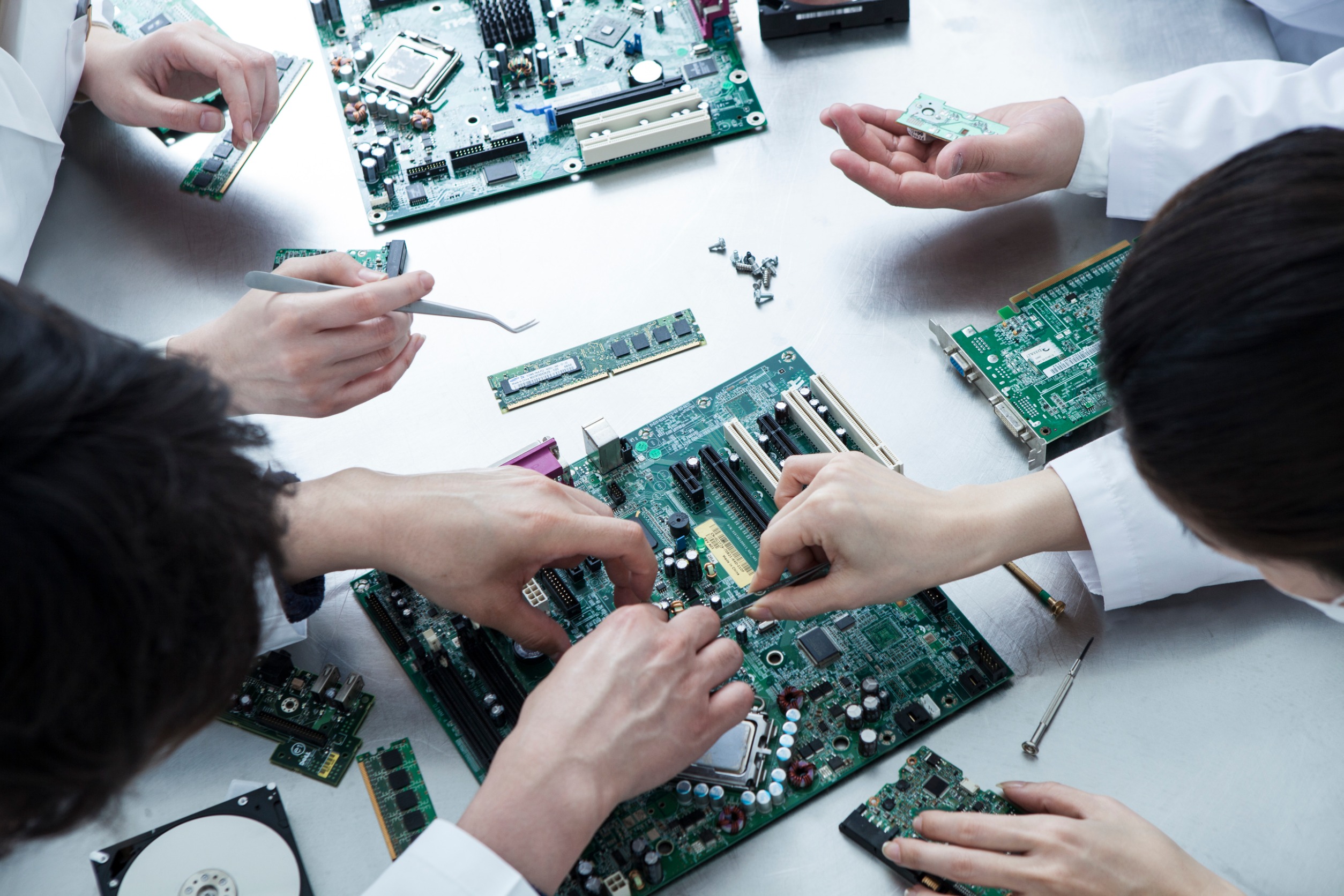

In the sprawling landscape of modern electronics, the printed circuit board assembly or PCBA process stands as a pivotal foundation, breathing life into components and transforming them into functional devices. However, as technology leaps forward, companies face a crucial decision – to build in-house or outsource their PCB assembly needs. This choice is becoming increasingly clear, with a growing trend towards outsourcing revealing its numerous advantages.

The Shift towards Outsourcing

The transition towards outsourcing PCB assembly is driven by the dynamic demands of the electronics industry, where speed, efficiency, and technological advancement are paramount. Companies across the globe are recognizing that outsourcing offers a strategic advantage, enabling them to stay agile and responsive in a competitive market.

Benefits of Outsourcing PCBA

1. Cost Savings and Efficiency

One of the most compelling reasons to outsource PCB assembly is the significant cost savings it offers. By leveraging the expertise and economies of scale of specialized PCB assembly providers, companies can reduce their manufacturing expenses and eliminate the need for hefty investments in production facilities and machinery. Outsourcing also streamlines the assembly process, enhancing efficiency and enabling quicker turnaround times.

2. Access to Sophisticated Technology

Outsourcing PCB assembly provides access to state-of-the-art technology and machinery without the need for direct investment. Specialized PCBA providers continually update their equipment and processes to stay at the forefront of technology, allowing their clients to benefit from the latest advancements and innovations in assembly methods.

3. Focus on Core Business

Outsourcing PCB assembly allows companies to concentrate on their core competencies, whether it’s research and development, marketing, or customer service – by offloading the intricate and time-consuming assembly process to experts. This focus can lead to improved products and services, driving growth and success.

4. Quality Assurance

Quality is paramount in PCB assembly, as it directly impacts the functionality and reliability of electronic devices. Outsourcing to reputable PCB assembly providers ensures that products are assembled to the highest standards, undergoing rigorous quality control checks. This expertise in assembly processes can significantly enhance the overall quality of products.

Challenges and Considerations

While outsourcing PCB assembly offers numerous advantages, it’s not without its challenges. Communication barriers, time zone differences, quality control, and intellectual property protection are critical considerations. However, with careful planning, clear communication protocols, and strategically chosen outsourcing partners, these challenges can be effectively managed.

Case Studies

Several companies have reaped the rewards of outsourcing their PCB assembly needs. From tech startups to established electronics manufacturers, the benefits manifest in reduced costs, improved product quality, and heightened competitive edge. These real-world examples serve as a testament to the strategic value of outsourcing PCB assembly.

Conclusion

The decision to outsource PCBA can be a game-changer for companies in the electronics sector. The myriad of benefits, from cost savings and increased efficiency to access to the latest technologies and heightened product quality, underscores its strategic value. By leveraging the expertise of specialized PCBA providers, companies can focus on their core operations, fostering innovation and driving business growth. If your company is navigating the complexities of PCB assembly, consider the strategic benefits of outsourcing. Transform your assembly process, capitalize on advanced technologies, and elevate your products to new heights. Explore the possibilities with an experienced PCB assembly partner and unlock the full potential of your electronic devices.