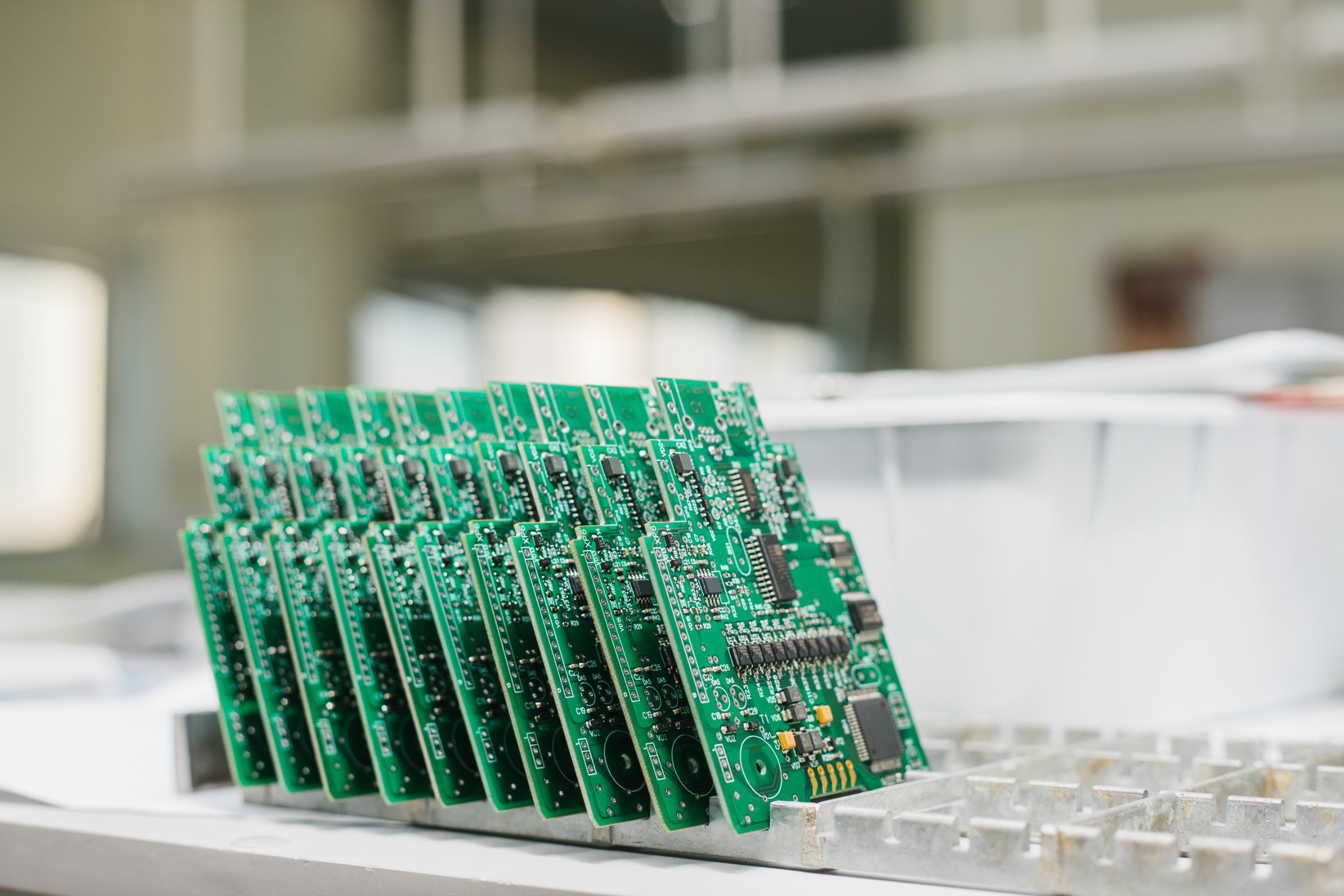

In the rapidly evolving world of electronics, the backbone supporting the majority of technological advancements is an unsung hero, which is the printed circuit board or PCB. PCBs are crucial for the functionality and operation of nearly all electronic devices. Yet, not all PCBs are created equal. Say hello to the Metal Core PCB or MCPCB, a game-changer in the domain of electronics.

What are MCPCBs?

Metal Core PCBs are a unique class of PCBs that utilize a metal material as their base for heat dissipation. Unlike traditional fiberglass or epoxy-based PCBs, the core material in MCPCBs is designed to redirect heat away from critical components, thereby enhancing the overall performance of the device.

Core Material and Its Benefits

The core of an MCPCB is usually made of aluminum, copper, or a mix of special alloys, which are renowned for their excellent thermal conductivity. This key feature allows MCPCBs to manage heat more efficiently than their non-metal counterparts, making them an ideal choice for high-power applications.

What are the advantages of MCPCBs?

The benefits of integrating MCPCBs into your electronic projects are vast, touching on everything from durability to performance.

1. Thermal Management

One of the paramount advantages of MCPCBs lies in their superior thermal management. By efficiently dissipating heat, MCPCBs prevent hot spots and minimize the risk of overheating, thus ensuring the longevity and reliability of the device.

2. Enhanced Durability and Reliability

Thanks to their robust construction and superior heat handling, MCPCBs offer increased durability. This means devices are less likely to suffer from issues related to thermal stress, such as warping or mechanical failure.

3. Improved Electrical Performance

Metal Core PCBs not only excel in heat management but also offer improved electrical performance. The enhanced thermal stability allows electronic components to operate within optimal temperature ranges, thereby ensuring consistent performance.

What are the Applications of MCPCBs?

The remarkable features of MCPCBs make them an excellent choice for a wide range of applications. Especially critical are industries where high power and reliability are non-negotiable, such as:

- LED lighting systems

- Automotive systems

- Power supplies

- Medical devices

- Consumer electronics

Why Choose a Metal Core PCB?

Opting for MCPCBs in your electronics projects comes with several compelling benefits:

Cost-effectiveness in the Long Run

While the initial investment in MCPCBs might be higher compared to standard PCBs, their durability and efficiency translate to lower maintenance and replacement costs, making them a cost-effective choice over time. Without a doubt, you can save a lot of money in the long run.

Environmental and Safety Benefits

The exceptional heat dissipation of MCPCBs not only protects the components but also contributes to environmental safety by reducing the risk of overheating-related hazards.

A Few Case Studies

Real-world applications of MCPCBs offer tangible proof of their impact. For instance, in the LED lighting industry, transitioning to MCPCBs has resulted in fixtures that are not only brighter but also more efficient and longer-lasting. Similarly, automotive and medical devices that incorporate MCPCBs have shown significant improvements in reliability and performance.

Final Words

The advancement of electronic devices is heavily reliant on the quality and capabilities of their underlying PCBs. A metal Core PCB stands out as a superior choice for any project where heat management, durability, and performance are of paramount importance. Choosing MCPCBs means investing in the future of your electronic devices – making them cooler, more reliable, and efficient. If you are on the brink of starting a new project, consider the robust foundation that an MCPCB can offer. It is a decision that combines innovation, efficiency, and long-term value, ensuring your electronics not only meet but exceed expectations.